Our company develops the development the Bolivian filament – epoxy resin electric capacity type compound coat drive pipe, is profits from the domestic and foreign similar products the advanced design idea,the breakthrough traditional process uses one kind of electric capacity compound coat drive pipe new product which the original new compound materials and the manufacture processing technology develops. This product besides satisfies GB4109-1999, IEC60137-1995 and the related each newest standard, because but also its unique design craft has avoided in the domestic similar product a flange and easy oil leak and the long time movement lies between damages the fill –out the question. Below has the remarkable characteristic :

1.Does not have the oil, airless, does not have the filling material, does not need to maintain;

2.The design insulation allowance is big , maximum limit enhancement corona voltage;

3.Thermostable , the electrical specification is stable , does not have burning and the explosion hazard ;

4.The structure is compact , the volume is small , the weight is light ,does not fear the clash , the convenient main engine factory and user’s scene installs.

5.The Bolivian filament –epoxy material from inside to outside to outside for the structure close solid state material ,used the unique craft to guarantee product in under long-term movement condition its electric power department proposed exempts the maintenance the request .

6.The production cycle was short , but also might carry on the special design according to the user request ,

7.Used the silica gel compound coat and according to 2 level of above antifouling rank designs. May satisfy the different contamination situation requirements.

| Model | Total length of casing | Wiring teminal | Compound extemal insulation | Flange | ||||||||||||||||||

| Hole number and diameter | Hole distance | Panel surface | Panel thickness | Cable entry length | Head diameter | Lead wire comection aperture | Insulation distance | Nominal creepage distance | Maximum shed diameter | Outer diameter of flange plate | Center diameter of installation hole | Hole number and diameter | Inner diameter of sealing surface | Center distance of vent hole | Total length of impregnated part | body diameter in the oil | Insulation length of oil end | Average pressure ball | Inner diameter of contact tube | Caing weight | ||

| FBRGW72.5/630-800 | 1515 | 4*14 | 40 | 80*80 | 10 | 1290 | 138 | 28 | 740 | 2250 | 232 | 290 | 250 | 6*18 | 160 | 72 | 390 | 116 | 0 | 60 | 40 | 46 |

| FBRGW72.5/630-800 | 1915 | 4*14 | 40 | 80*80 | 10 | 1690 | 138 | 28 | 740 | 2250 | 232 | 290 | 250 | 6*18 | 160 | 72 | 790 | 116 | 400 | 60 | 40 | 57 |

| FBRGW72.5/1250 | 1520 | 4*18 | 50 | 100*100 | 13 | 1290 | 138 | 32 | 740 | 2250 | 232 | 290 | 250 | 6*18 | 160 | 72 | 390 | 116 | 0 | 60 | 40 | 47 |

| FBRGW72.5/1250 | 1920 | 4*18 | 50 | 100*100 | 13 | 1690 | 138 | 32 | 740 | 2250 | 232 | 290 | 250 | 6*18 | 160 | 72 | 790 | 116 | 400 | 60 | 40 | 58 |

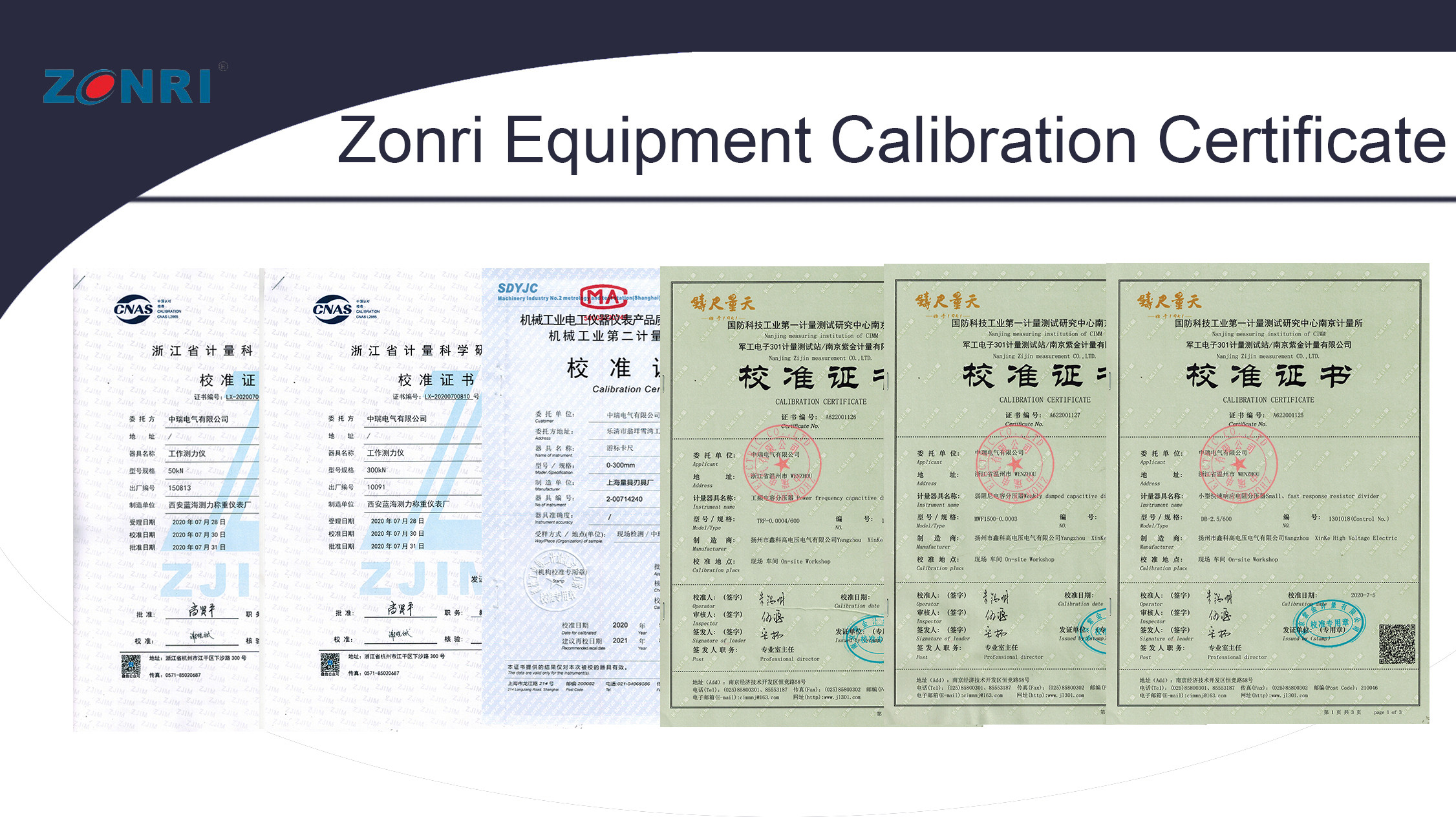

Only a good machine can produce cost-saving, high-quality products, so annual calibration and calibration certificates are very necessary, and other manufacturers basically do not do calibration.

Our company diversifies the production of various types of insulators, so as to better meet the needs of various countries and customers. No need to ask customers to find a second company. Save a lot of time and cost for customers.

Our company uses a variety of publicity methods, such as website optimization, GOOGLE, exhibitions, magazines, etc.