Drop-out fuse is the most commonly used short-circuit protection switch for branch lines and distribution transformers of 24kV distribution lines.

The drop-out fuse is installed on the branch line of the 24kV distribution line, which can reduce the scope of power failure. Because it has an obvious disconnection point, it has the function of an isolation switch, which creates a safe working environment for the lines and equipment in the maintenance section.

Installed on the distribution transformer, it can be used as the main protection of the distribution transformer.

It has the characteristics of economy, easy operation and strong adaptability to outdoor environment. It is widely used in 24kV distribution lines and the primary side of distribution transformers for protection and equipment switching and switching operations, and has been popularized.

This product has passed the European 7.2kA 10kA breaking test。

|

Model |

Rated voltage

kV

|

Rated current

A

|

creepage distance

mm

|

Rated circuit break current

kA

|

Impulse voltage

kV

|

P.F.withstand voltage

kV

|

standard |

|

HRW12-24/100 |

24 | 100 | 560 | 7.2 | 125 | 50 |

IEC 60282 |

| HRW12-24/100 | 24 | 100 | 560 | 10 | 125 | 50 | IEC 60282 |

Use environmental conditions:

1. The normal use conditions of the product: the ambient temperature is not higher than +40 degrees, not lower than -40 degrees; the altitude is not more than 1000m; the maximum wind speed is not more than 35m/s; the earthquake intensity is not more than 8 degrees.

2. The product is not suitable for the following places: places with danger of burning or explosion; places with severe vibration or shock; places with conductive, chemical gas effect and serious pollution of salt spray.

Operation attention

Under normal circumstances, it is not allowed to operate the drop-out fuse with load, and it is only allowed to operate the no-load equipment (line). However, branch lines of 24kV distribution lines in rural power grids and distribution transformers with rated capacity less than 200kVA are allowed to operate with load according to the following requirements:

(1) The operation shall be carried out by two persons (one to monitor and one to operate), but must wear qualified insulating gloves, insulating boots and goggles, and operate with qualified insulating rods with matching voltage levels. Operation is prohibited in heavy rain.

(2) During the operation of the gate, it is generally stipulated that the middle phase is pulled off first, then the leeward side phase is pulled, and finally the windward side phase is pulled off. This is because the distribution transformer is changed from three-phase operation to two-phase operation, and the arc spark generated when the intermediate phase is broken is the smallest, which will not cause short-circuit between phases. The second is to break the leeward side phase, because the middle phase has been pulled apart, and the distance between the leeward side phase and the windward side phase has doubled. Even if there is an overvoltage, the possibility of short circuit between phases is very small. When the windward phase is finally broken, there is only a capacitive current to the ground, and the spark generated is very slight.

(3) When closing, the operation sequence is reversed when closing, first close the windward side phase, then close the leeward side phase, and finally close the middle phase.

(4) The operation of the melting tube is a frequent item. If it is not noticed, it will cause the contact to burn and cause poor contact, overheat the contact, and anneal the spring, which will make the contact worse and form a vicious circle. Therefore, when pulling and closing the fusion tube, use moderate force. After closing, carefully check that the duckbill tongue can be tightly buckled for more than two-thirds of the length of the tongue. You can use the brake lever to hook the upper duckbill and press down a few times. Try pulling again to check if it fits properly. When the switch is closed, it is not in place or not firmly closed, and the static contact pressure on the fuse is insufficient, which can easily cause the contact to burn or the fuse tube to fall by itself.

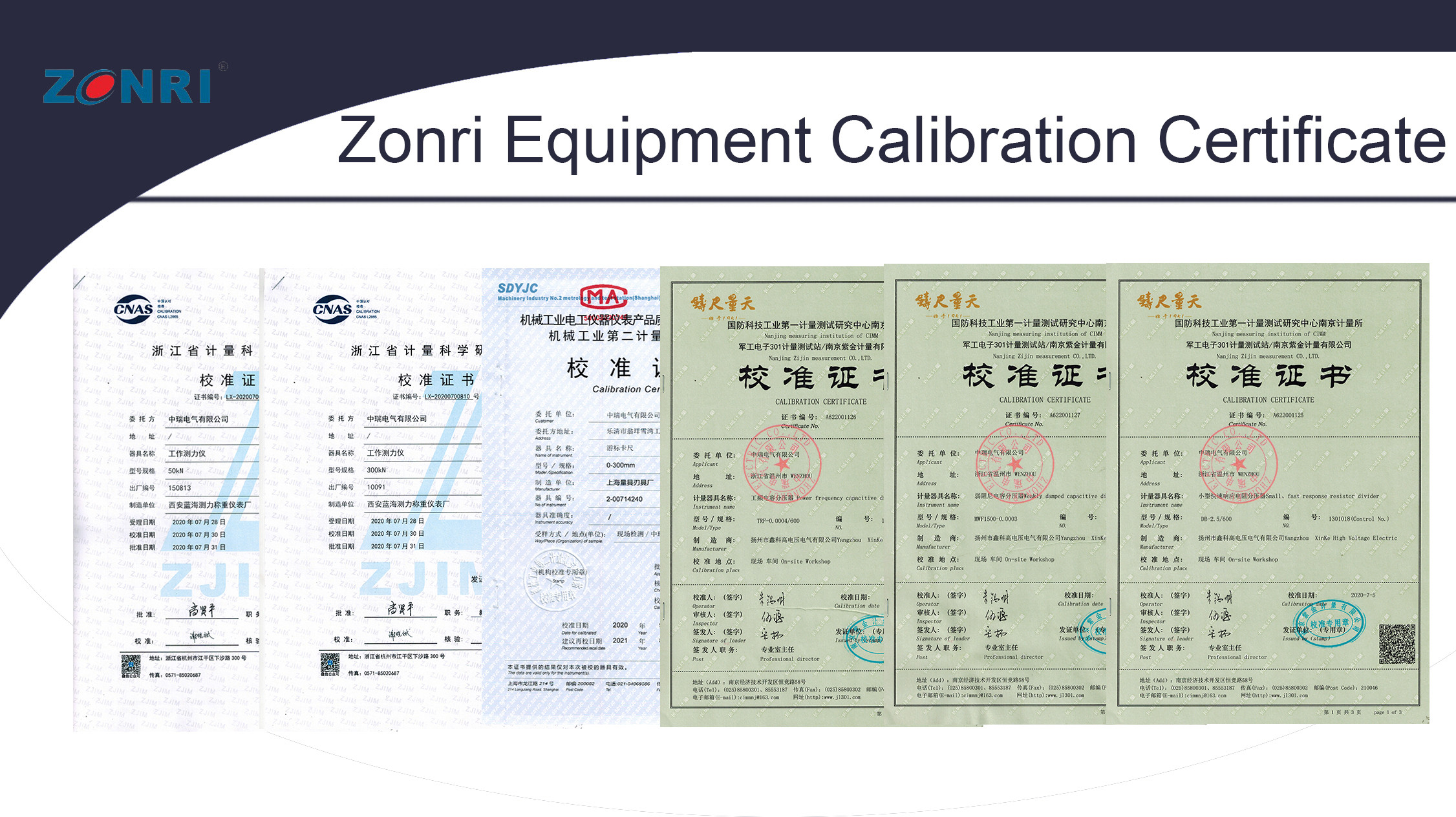

Our products are produced in strict accordance with the IEC standard order.

All production equipment is also calibrated in accordance with IEC standards in a timely and punctual manner to ensure product quality

We have laboratories that comply with IEC standards to ensure the correctness of each data given to customers